Top-Tier Materials

for Advancing

Enteral Devices

In the realm of medical device manufacturing, the pursuit of excellence and innovation is paramount. This is why we use only high-quality materials for the manufacture of our products to ensure long product life and safe application.

- High-grade medical Silicone for our gastrostomy tubes

- Soft, flexible Polyurethane for our Extension Set tubings

- Break-resistant TRITAN™ for our enteral connectors

Polyurethane

We prefer Polyurethane (PU) over PVC for the tubing of our danumed® Extension Sets due to its exceptional qualities:

- High Biocompatibility

Polyurethane is a biocompatible material, reducing the risk of adverse reactions and irritation, making it suitable for long-term use. - No Need For Plasticizers

Unlike PVC, polyurethane does not require plasticizers to remain flexible and soft. Plasticizers like phthalates can leach harmful substances with potential health risks for patients. - Resistance To Kinking

Polyurethane tubes are less prone to kinking, which is crucial for maintaining a consistent flow in enteral feeding. - Durability And Flexibility

PU remains its flexibility and elasticity over time and also has excellent tensile strength and elongation properties. - Enhanced Flow Range

PU tubes typically have thinner walls than PVC tubes, providing a larger inner diameter while maintaining the same outer diameter, thus enhancing the flow area for enteral feeds. - Patient Comfort

Polyurethane is softer, more flexible and more comfortable for patients, especially for long-term or sensitive applications.

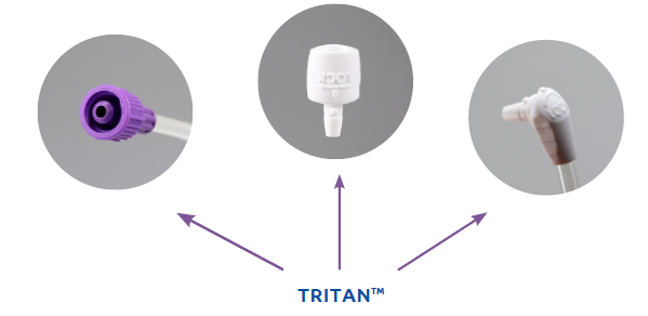

TRITAN™

TRITAN™ is our material of choice for our button connectors and for the core pieces of our ENFit® connectors for the following reasons:

- Durability: It is a lightweight, robust plastic material known for its resistance to aggressive solutions and medicines.

- Stress crack resistance: TRITAN™ reduces the risk of stress cracks and supports the break-resistant application of enteral devices.

- Structural integrity: It can withstand the rigors of everyday use without compromising the device’s structural integrity.

Considering these factors, we are confident that TRITAN™ can greatly enhance the reliability, safety and longevity of our danumed® products.

Latex-free / DEHP-free / BPA-free

For the manufacture of all our enteral feeding products, we uncompromisingly use high-quality materials, all of them are latex-free, DEHP-free and BPA-free. Using materials that are biocompatible and non-toxic is essential to safeguarding the health of vulnerable patients who rely on safe enteral applications for their nutritional and medical needs.

References:

Silk D, Quinn D. Dual-purpose gastric decompression and enteral feeding tubes rationale and design of novel nasogastric and nasojejunal tubes. JPEN J Parenter Enteral Nutr. 2015;39(5).

Zdrahala R, et al. Biomedical Applications of Polyurethanes: A review of past promises, present realities and a vibrant future. J Biomater Appl. 1999;14.

Bergeron M, Guidoin R, et al. Biomedical Applications of Polyurethanes. In: Chapter 8, 2001.

Best C. Nutrition Nurse Specialist, Royal Hampshire County Hospital, Winchester. Nursing Times (Online). 2019;115(3).

Tronnier V, et al. Ösophagusperforation und Pneumothorax – Komplikationen durch Legen einer Magensonde (Fallbericht). Anasthesiol Intensivmed Notfallmed Schmerzther. 1991;26.

Welle F, et al. Migration von Weichmachern aus PVC Schläuchen in enterale Nahrungslösungen. Pharma Int. 2005;3.

Cervera M, et al. Evaluation of the elastic behaviour of central venous PVC, polyurethane and silicone catheters. Phys Med Biol. 1989;34.

Eastman Brochure. Chemical compatibility with hospital disinfectants and oncology drugs. Eastman. 2014;September.

Eastman Brochure. Lipid and Isopropanol Resistance of Eastman Polymers in Medical Devices. Eastman. 2007;September.

Eastman Brochure. Redefining the balance between processability and chemical resistance. Eastman. 2009;February.

Interested in further danumed products and features?